Revolutionize your operations

OTRS is time and motion analysis software designed to help you achieve labor and cost reductions within your operations.

Design, analyze and implement standardized work to eliminate overburden, waste and unevenness within your operations.

The software leverages Japanese industrial engineering and lean manufacturing approaches to help your company achieve world-class performance.

Now Available in Dongle, Network and Mobile Editions!

Boost your Productivity with OTRS

Shoot the Video.

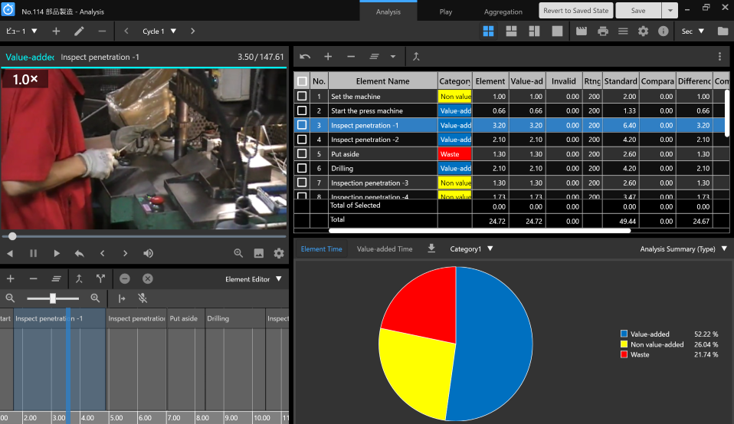

Analyze the Process.

With a user interface specifically designed for video analysis, closely analyze detailed motions by simply using your mouse. Cycle analysis is also available to make it easier than ever to discover any variations that appear in your work.

Eliminate Waste.

Standardize the Process.

Through comparison of two videos that differ in process, easily verify and correct any issues. Along with general playback features, OTRS also allows for reverse playback, frame-by-frame playback and more to help eliminate patterns that are not efficient or are problematic.

Rearrange Elements.

Optimize your Workflow.

OTRS allows you to reposition tasks and run a process simulation with the task in the new position. It also allows you to output Standardized Work Combination Chart, which visualize which parts of the process have improved and how much.

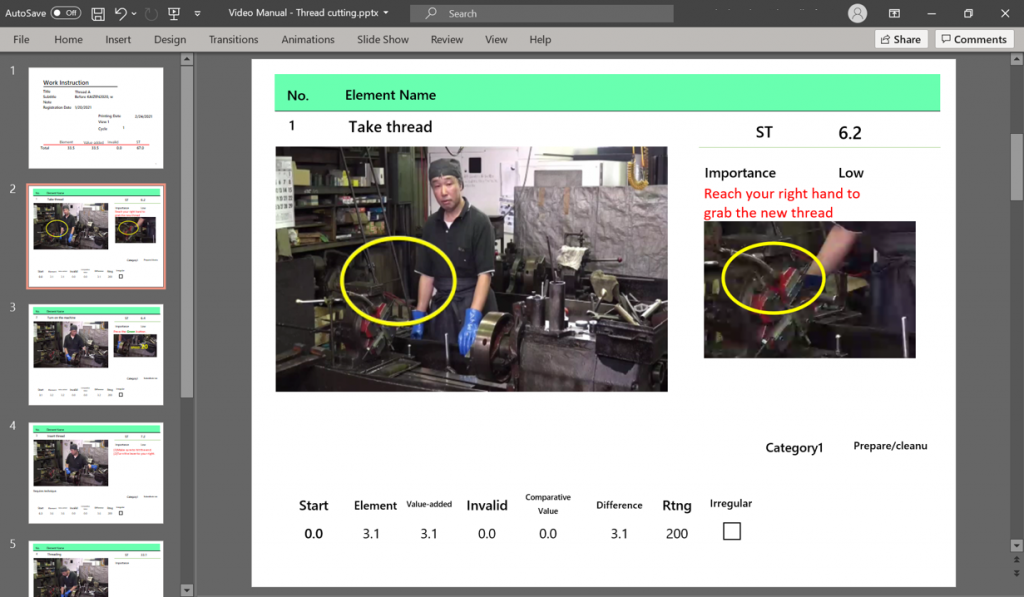

Transfer Skills.

Train Staff.

Analysis results can be shared as a video manual through PowerPoint®. Narrations can also be added, creating content that is more effective and efficient in explaining processes to new workers or foreigner workers. It is also the perfect tool to successfully share skills and create multi-skilled workers.

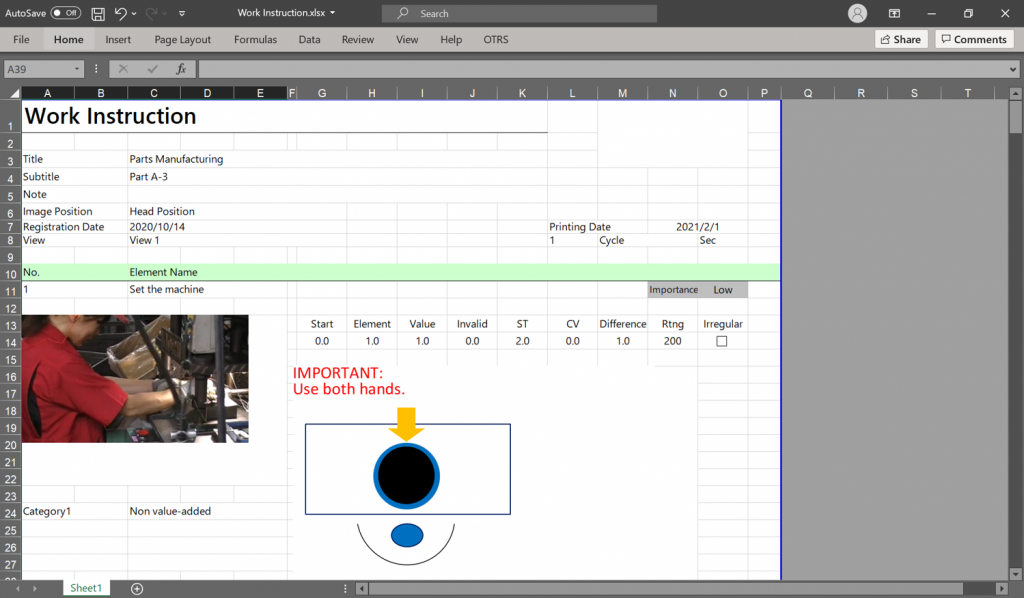

Customized for You.

Use the contents that has been analyzed through OTRS to create an Excel® document in the layout of your choice. This can be used to create documents to improve work standards or to create manuals and guides for workers to follow. Take a step towards better quality control and the 5S method.

Success Stories

Explore OTRS’ Case Studies from Multiple Industries