Outsourcing in electronics and embedded systems has become a practical strategy for companies looking to scale design capacity, accelerate development, or maintain legacy systems. Design engineering support, firmware development, and testing functions are increasingly handled by offshore engineering teams.

However, embedded systems are not forgiving. Poor scoping, unclear ownership, or weak documentation can introduce long-term technical and operational risk.

Before engaging an electronics engineering outsourcing partner, engineering leaders should pause and ask the right questions.

1. What Exactly Are We Outsourcing — Execution or Ownership?

In embedded systems, ownership determines who carries long-term risk and not just who does the work. When companies outsource without explicitly separating execution from ownership, decision-making becomes implicit, and accountability erodes.

Engineering leaders should be clear that:

- System architecture, safety decisions, and IP ownership typically remain internal.

- Outsourced engineers execute within defined technical boundaries.

When this boundary is not explicit, outsourced teams are forced to make assumptions. In embedded systems, assumptions about timing, tolerances, or interfaces often surface later as reliability or compliance issues — when they are hardest to fix.

Well-structured outsourcing preserves internal authority while extending execution capacity.

2. How Stable Are Our Existing Schematics, Firmware, and Documentation?

Embedded systems often evolve over years, accumulating undocumented changes, informal fixes, and design decisions that live only in engineers’ heads. Internal teams can work around this. External teams cannot.

Before outsourcing, leaders should assess whether:

- Schematics reflect what is actually built and shipped

- Firmware versions are traceable to hardware revisions

- Known constraints and trade-offs are documented, not implied

Outsourcing is most effective when documentation is treated as a shared engineering asset, not a historical artifact. If documentation is weak, outsourcing will magnify that weakness rather than compensate for it.

3. Is the Work Ongoing or Project-Based?

Many outsourcing challenges arise not from poor execution, but from mismatched engagement models.

Project-based work such as redesigns, validation efforts, or migrations — benefits from tight scopes, fixed deliverables, and defined end states. While ongoing work such as sustaining engineering, design updates, or product variants — requires continuity, institutional knowledge, and long-term collaboration.

Engineering leaders should align the outsourcing model to the nature of the work. Treating ongoing design support like a short-term project often leads to repeated onboarding, fragmented knowledge, and inconsistent output.

4. How Will We Transfer Context — Not Just Files?

Embedded systems are shaped as much by constraints as by specifications. Schematics and code rarely explain:

- Why certain components were chosen

- What alternatives were rejected

- Which compromises were intentional

Without this context, external engineers may technically “follow” the design while unintentionally violating its intent.

Successful outsourcing allocates time for:

- Design walkthroughs

- Explanation of assumptions and edge cases

- Ongoing access to internal reviewers

Context transfer is not a one-time activity. It is an ongoing part of collaboration, especially in systems with long lifecycles.

5. Who Reviews and Signs Off on the Work?

Outsourcing changes who does the work. In electronics and embedded systems, unchecked output can introduce risks that surface months later during testing, certification, or production.

Effective outsourcing arrangements clearly define:

- Who reviews schematics, firmware changes, and test results

- What standards must be met before acceptance

- How issues are escalated and resolved

Internal review is not a lack of trust. It is a recognition that responsibility for system integrity remains with the organization that owns the product.

6. Are We Accounting for Hardware, Compliance, and Testing Realities?

Embedded systems do not move at the pace of pure software. Hardware availability, test equipment, regulatory requirements, and certification timelines impose constraints that must be planned.

Before outsourcing, leaders should consider:

- How hardware dependencies affect schedules

- Whether applicable standards (IPC, EMC, ISO, product-specific requirements) are understood

- How validation and testing are integrated into the workflow

Many outsourcing frustrations occur when embedded work is scheduled as if iteration were unlimited and physical constraints did not exist.

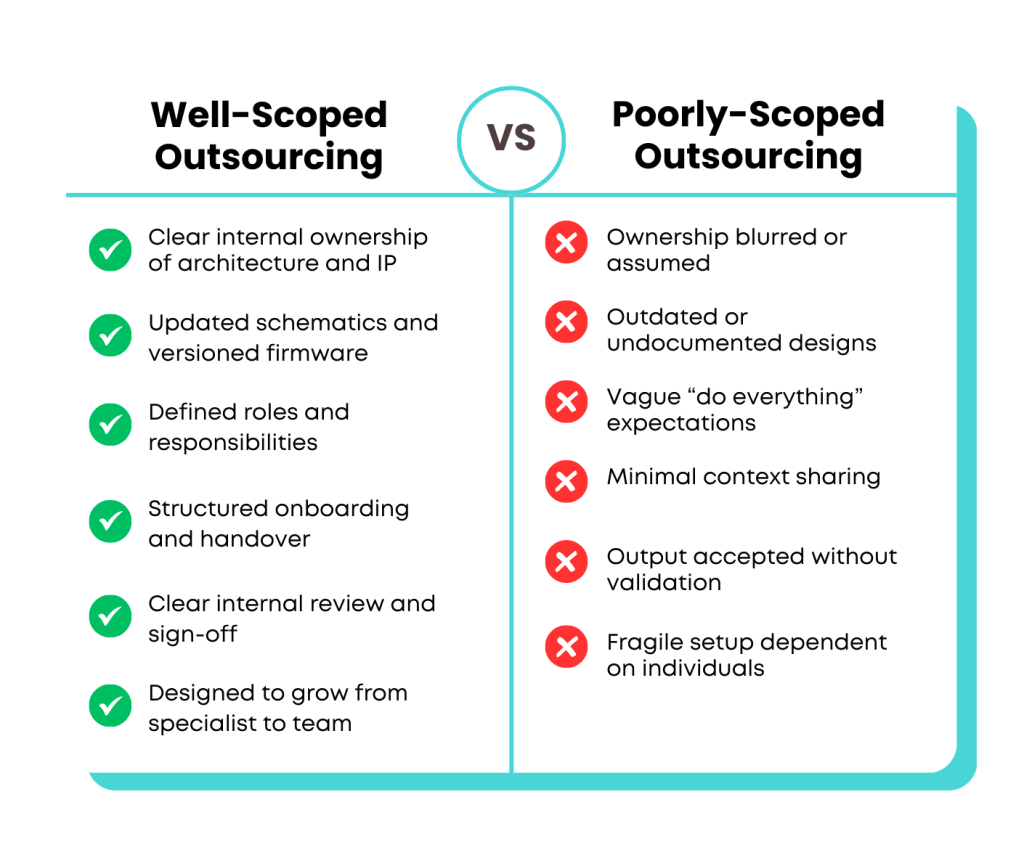

Embedded Systems Outsourcing: A Practical Comparison

This comparison highlights a critical pattern: outsourcing success is rarely about talent alone. It is about structure.

The difference between well-scoped and poorly-scoped outsourcing determines whether external engineering becomes a long-term capability or a recurring operational risk.

7. Can This Engagement Scale Without Losing Control?

Outsourcing arrangements that work tend to grow.

What begins as one engineer often expands into a small team supporting multiple products or variants. Without planning for scale, organizations risk fragmentation and loss of consistency.

Leaders should ask:

- How knowledge will be retained as the team grows

- How standards and design practices are enforced

- What happens if key individuals leave

Designing for scale early ensures that growth increases resilience rather than complexity.

A More Sustainable Way to Outsource Electronics & Embedded Systems

Strong engineering organizations do not outsource to avoid responsibility.

They outsource to protect focus, continuity, and internal expertise.

When approached thoughtfully, electronics and embedded systems outsourcing becomes a structured extension of the engineering organization — not a substitute for it.

At Weave, we support engineering-led organizations that want to extend their design capabilities without losing technical control. Our approach to electronics and embedded systems outsourcing emphasizes long-term design engineering support, clear ownership, and practical collaboration between offshore teams and internal engineering leadership.